Power supply for aeration (compensation) gates in production and warehouse halls

According to the technical knowledge commonly used on the market, compensation, i.e. the inflow of fresh air, plays a key role in smoke removal systems, which allows, among other things, to create a directed flow of gases resulting from combustion towards the smoke exhaust flap located on the roof of the facility to be ventilated. Speaking about smoke removal, there is a number of national and international standards and guidelines that also include compensation issues. It can be divided in the simplest way - into gravitational or mechanical. These methods are used interchangeably, depending on the system requirements and facility architecture.

In large production or storage halls, the most common technical solution is a smoke removal system using pneumatic power supplies; compressed air is transported through copper pipes, allowing the opening of smoke exhaust flaps equipped with pneumatic actuators. If there is a power failure in the vicinity of the constructed facility and a fire hazard occurs, the system powered only from the switch will not work properly. Roof flaps will be opened from certified pneumatic power supplies that are not affected by the lack of power supply to the facility or from smoke removal units equipped with batteries. Without certified power supplies for fire gates, there will be no energy to open the compensation holes. This problem will result in a lack of air flow, which will result in smoke accumulating, cooling down and falling into the evacuation route of people inside the building in a short time.

For a long time, there has been a growing interest in the market in solutions for powering compensation systems. Many facilities are equipped with power supplies for fire-fighting aeration gates, which ensure that the gate will operate even in the event of a mains power failure in the entire facility.

It should be noted that fire-fighting devices should be powered by fire-fighting power supplies, and in accordance with the provisions of the PN EN 12101-10 standard for electric power supplies, backup power sources may be:

• accumulator or battery bank,

• energy generator,

• second, independent power supply from the power grid.

For aeration gates power supplies, it is advised to use a battery bank.

In logistics facilities, which are still very popular after the pandemic, the smoke removal system plays an important role already at the design stage. In practice, the compensation function in smoke removal systems of these facilities is most often implemented gravitationally - through dock or entrance gates, called aeration gates for the purposes of this system.

During the process of hall's smoke removal system design, the technical conditions (TC) for this type of facilities and the requirements for fire protection systems should be taken into account, including a method of power supply during a fire. It should also be remembered that power supply only from the building's fire protection switch - although specified in the Technical Conditions - used as the only form of emergency power supply is not an effective solution ensuring the safety of people and property. In the event of a power outage in the entire facility, power will also be unavailable upstream of the fire protection switch. The use of uninterrupted power supply results from the requirements of the smoke and heat control system (commonly smoke removal), and not from the technical conditions of the facility itself.

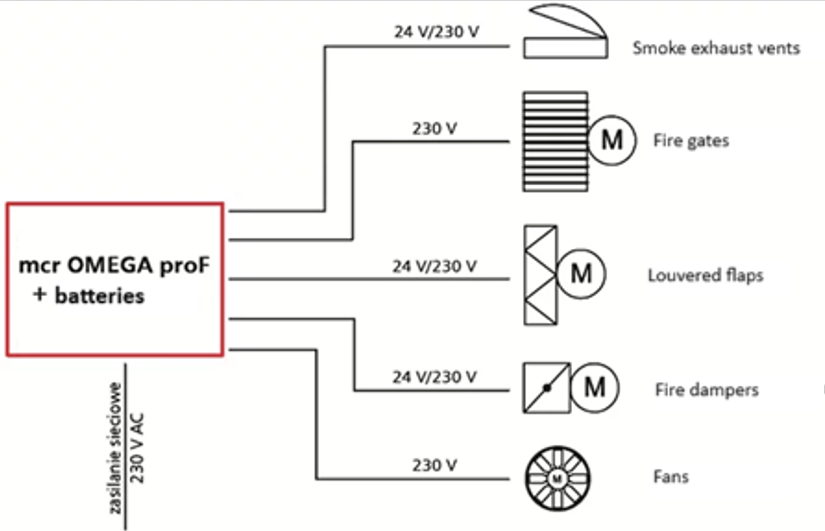

In 2017, MERCOR was the first company in Poland to introduce to the market a certified solution for powering air gates - the mcr OMEGA proF fire. It is at once a protection device with a power supply, which is successfully used in construction. This solution provides a range of output powers from 400W to 3000W, allowing you to power a wide range of devices - from fire dampers through aeration gates, including large-sized high-speed gates, to fire protection fans.

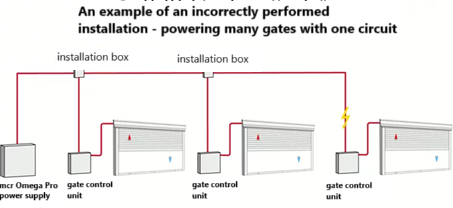

Using certified fire protection devices, the installation of the systems in which they are installed should also be carried out in accordance with applicable standards, regulations and guidelines. In the era of widespread optimization, which is usually motivated by financial reasons, a very common error is designing one power supply output powering several fire protection gates at the same time.

As the manufacturer of the device, MERCOR declares that the output power will be maintained at a constant level, appropriate for a given power supply model (from 400W to 3000W), as well as the possibility of overloading the device in a specific percentage range and time period, but in the basic version of this device only one output is protected. In practice, this means that in the event of a failure (e.g. short circuit) of one of several connected devices, all other devices will also lose their power supply (primary and reserve).

The mentioned situation is described on the following scheme:

It is worth mentioning that power supply used in mcr OMEGA pro, allows a guaranteed power supply of low-power three-phase fans (up to 2.2 kW), e.g. in mechanical smoke removal systems for staircases.

MERCOR devices, in accordance with production standards and regulatory requirements, are standardly equipped with inputs/outputs for control and control by superior systems, such as the SSP, SIUP or BMS system. Responding to market needs and increasing the level of security regarding uninterrupted power supply, the mcr OMEGA pro power supply is equipped with a special alarm input that allows it to be activated only in the event of a fire hazard. Lack of power in the facility is not a sufficient reason to operate the aeration gate from batteries, e.g. for purposes other than smoke removal, i.e. unloading cars, ventilation.

Using this input allows you to save the energy stored in the batteries only for the risk of the fire. The power supply outputs have also been prepared to ensure maximum safety. In addition to the basic outputs signaling the power supply status - failure and operation confirmation - the device has an additional time output operating with a delay in relation to the alarm output. This allows the gate controller to be started after the power supply switches to emergency mode, also in the event of a mains power failure while the gate is opening. Most gate controllers respond to the tuning edge signal and in the event of a short power outage of the gate controller, it does not respond to the permanently incoming fire signal "locked" at the output of the SSP control module. The power supply has a time-off function, which is often used in connection with hall sprinkler systems. After the programmed time, counting from the alarm signal, the power supply will turn off, allowing the sprinkler system to operate without the risk of damage to the devices (e.g. short circuit) or electric shock to people taking part in the rescue operation.

In order to eliminate the problem, use power supplies designed to operate each gate separately, selected for the electrical power supply, while ensuring protection for each device.

Another important aspect is that when several gates are powered from one power supply, the issue of selecting the appropriate battery capacity is often omitted, while the several gates are powered from basic batteries. This practice, although it allows for effective opening of the gates, causes the system to function at the limit of reliability, using up the "reserve" provided by the manufacturer. Designers and contractors should remember that each time the battery capacity should be calculated for a given application.

It’s worth to remember that the smoke removal system is used to improve the safety of evacuation of people in the event of a fire hazard and should guarantee the highest effectiveness, therefore, at each stage of the construction of the facility, special attention should be paid to its proper implementation, bearing in mind the applicable fire protection rules and regulations.

In case of any questions about smoke removal devices and systems, please contact the technical department of MERCOR S.A.

Wojciech Płaczek

Head of the fire automation team in Mercor SA